Spice Dryer Machine

Quick Specification

| Materials | Dry Chilli, Coriander & Cumin, Peanut, Cashew, Pista, Almond etc |

| Output | ~200 Ltr/batch |

| Power |

10 kWh (6 Unit/hr) |

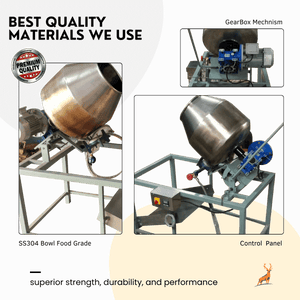

| Body Options | SS202 Body & SS304 Food Grade Bowl |

Before You Buy

- Confirm your required kg/hr output + mesh fineness on your material.

- WhatsApp your material name + target kg/hr to get the right model + HP suggestion.

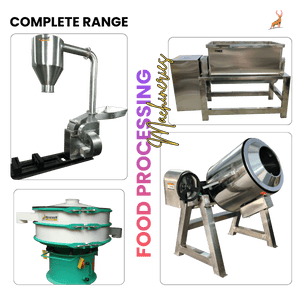

- View all Roasting Machine machines.

187K+ Subscribers

500+ Google Reviews

Export to 30+ Countries

Warranty + Spares Support

Not sure which Machine you need?

Share material name + required kg/hr on WhatsApp — we’ll suggest the right model + HP recommendation.

Spice Dryer Machine

| MODEL | HAD200 |

|---|---|

| Rosting Capacity | ~200 Ltr/batch |

| Grinding Materials | peanut, spices, seeds, grains etc. |

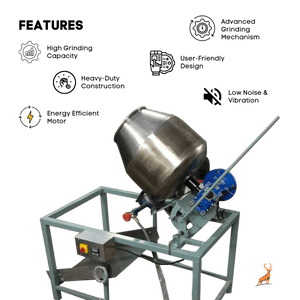

| Electric Motor | 1 HP |

| Motor Brand | Mill Power Motor |

| Gear Box | Elecon GearBox |

| Heater | 9 kVA |

| Phase | Three Phase |

| Voltage | 440V, 50Hz |

| Power Consumption | 10 kWh (6 Unit/hr) |

| Power Type | Electric + Hot Air Dryer |

| Temperature Control | up to 200 C |

| Body Structure | SS202 Body & SS304 Food Grade Bowl |

| Dimension (LxWxH) | 6' x 5' x 6' (feet) |

| Foundation Required | Not Required |

Model Range

| RDM50 | ~50 ltr/batch & 0.5 HP Motor |

|---|---|

| RDM100 | ~100 ltr/batch & 0.5 HP Motor |

| RDM150 | ~150 ltr/batch & 1 HP Motor |

| RDM200 | ~200 ltr/batch & 1 HP Motor |

| RDM250 | ~250 ltr/batch & 2 HP Motor |

| RDM300 | ~300 ltr/batch & 2 HP Motor |

Not sure which Machine you need?

Share your material name + required kg/hr on WhatsApp — we’ll suggest the right model.