Peanut Peeling Machine

Quick Specification

| Plant Includes | 1) Peanut Drum Roaster (SS304) + 2) Peanut Skin Remover (PPM) + 3) Peanut Butter Machine (PBM) |

| Application Materials | Peanut, cashew, chilli, and similar food-grade grinding materials |

| Body (Food Grade) | SS304 Food Grade (All Machines) |

| Roaster Models | DR60 / DR100 / DR200 / DR300 (SS304) |

| Roaster Batch Size | DR60: 66 L | DR100: 110 L | DR200: 155 L | DR300: 200 L |

| Roaster Power | DR60: 0.5 HP | DR100: 0.5 HP | DR200: 1 HP | DR300: 1 HP |

| Roaster Electrical Load | DR60: 9 KVA | DR100: 11 KVA | DR200: 18 KVA | DR300: 24 KVA |

| Roaster Controls | Heating Element + Temperature Controller + Temperature Display + Gearbox Mechanism |

| Peanut Skin Remover | Model: PPM | Power: 3 HP | 2.2 kW |

| Peanut Butter Machine | Model: PBM | Power: 1.25 HP | 920 W |

| Brand | Reindeer Machinery |

Before You Buy

-

Selecting the right peanut peeling machine depends on your roasting batch size and the required peeling efficiency for clean kernels. Matching capacity with airflow ensures stable performance and minimal kernel loss.

Explore options in our peanut skin peeler category to compare suitable models.

187K+ Subscribers

500+ Google Reviews

Export to 30+ Countries

Warranty + Spares Support

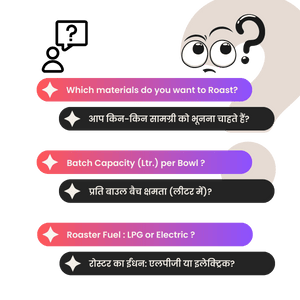

Not sure which Machine you need?

Share material name + required kg/hr on WhatsApp — we’ll suggest the right model + HP recommendation.

Peanut Peeling Machine

| MODEL | Rosted Peanut Peeling Machine |

|---|---|

| Production Capacity | ~60 to 80 Kg/Hr |

| Materials | Peanut |

| Electric Motor | 3 HP |

| Motor Brand | Mill Power |

| Ele. Motor RPM | 1440 RPM |

| Phase | Single and Three Phase |

| Voltage | 220V or 440V, 50Hz |

| Power Consumption | ~2.5 kWh |

| Body Structure | SS202 |

| Weight | ~80 kg |

| Foundation Required | No |

Model Range

| DR60 SS304 | 0.5 HP |

|---|---|

| DR100 SS304 | 0.5 HP |

| DR200 SS304 | 1 HP |

| DR300 SS304 | 1 HP |

| Includes | heating element, temp controller, temp display, gearbox motor |

| Peanut Skin Remover (PPM) | 3 HP |

| Peanut Butter Machine (PBM) | 1.25 HP |

Not sure which Machine you need?

Share your material name + required kg/hr on WhatsApp — we’ll suggest the right model.