spices pulverizer

\n

Regular price

Rs. 26,640.00

Sale price

Rs. 22,200.00

Unit price

per

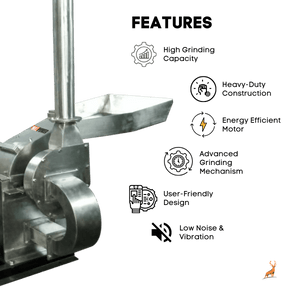

Quick Specification

| Materials | Chilli, coriander, cumin, dry masala, herbs, dry leaves, clove, cinnamon, cardamom, etc. |

| Output | 20–50 kg/hr (depends on HP, material & mesh) |

| Power | 2 HP, 3HP and 5 HP |

| Fineness (Mesh) | Upto 50 mesh |

| Body Options | MS (Mild Steel) or SS304 Food Grade |

Before You Buy

- Confirm your required kg/hr output + mesh fineness on your material.

- WhatsApp your material name + target kg/hr to get the right model + HP suggestion.

- View all masala grinding machines.

187K+ Subscribers

500+ Google Reviews

Export to 30+ Countries

Warranty + Spares Support

Not sure which Machine you need?

Share material name + required kg/hr on WhatsApp — we’ll suggest the right model + HP recommendation.

spices pulverizer

Get Quotation / Support in 30–60 Minutes

Working hours : Mon - Sat (10 am to 7 pm)

Not sure which Machine you need?

Share your material name + required kg/hr on WhatsApp — we’ll suggest the right model.

| MODEL | BP3 |

|---|---|

| Production Capacity | 30 Kg/Hr |

| Grinding Materials | Chilli, coriander, cumin, dry masala, dry leaves, clove, cinnamon, cardamon, herbs etc. |

| Electric Motor | 3 HP Crompton Motor IE2 ISI |

| Motor Brand | CG - Crompton |

| Ele. Motor RPM | 1440 RPM |

| Phase | Single and Three Phase |

| Voltage | 220V or 440V, 50Hz |

| Power Consumption | 2.2 kWh |

| Mechanism RPM | ~3000 RPM |

| Chamber Size | 10" x 5" |

| Body Structure | MS full Body or Full body SS304 Food Grade |

| Contact Parts | MS full Body or Full body SS304 Food Grade (on Demand) |

| Weight | 100 kg |

| Dimension (LxWxH) | 4' x 3' x 4' (feet) |

| Accessories | 3 Sieves, 2 Clothes (Anti-Vibration pad, Anchor Fastener Extra) |

| Foundation Required | Yes or Anti-Vibration Pad |