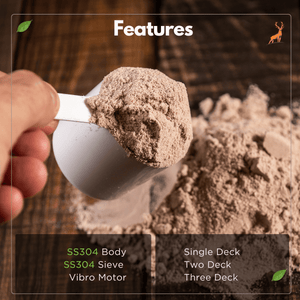

Vibro Sifter Machine 30 Inch | Vibrating Sifter

Quick Specification

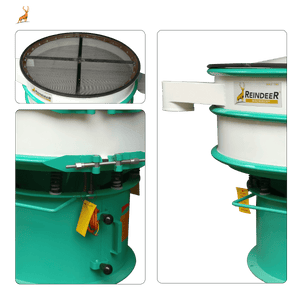

| MODEL | VS30 SS304 |

| Screen Diameter | 30" single Deck |

| Production Capacity | Depends on ⌀ Diameter of Sieve & Inlet and outlet Powder fineness. |

| Application | Seperate Presized Powder Mesh from Powder Raw Material |

| Electric Motor | Vibro Electric Motor |

| Voltage | 415 V, 50 Hz Three Phase |

| Body Structure | Full Body SS304 |

| Weight | 110 kg |

| Dimension | 35" x 35" x 30.5" |

| Motor Hp | 0.5 Hp |

| Material | Any Powder Like Chilli powder, coriander powder, turmeric powder, mix masala powder etc.. |

Before You Buy

- Watch the machine in action to understand sieving efficiency and vibration accuracy.

This video demonstrates real-time performance from our vibro sifter machine range under Our Vibro Shifters.

Ideal for buyers evaluating compact, low-power screening solutions.

187K+ Subscribers

500+ Google Reviews

Export to 30+ Countries

Warranty + Spares Support

Not sure which Machine you need?

Share material name + required kg/hr on WhatsApp — we’ll suggest the right model + HP recommendation.

Vibro Sifter Machine

Get Quotation / Support in 30–60 Minutes

Working hours : Mon - Sat (10 am to 7 pm)

Not sure which Machine you need?

Share your material name + required kg/hr on WhatsApp — we’ll suggest the right model.

| MODEL | VS30 |

|---|---|

| Production Capacity | Depends on sieve size and Powder raw material |

| Shifting Materials | Used for screening and grading powders/granules to remove oversize particles, lumps, dust, and impurities. Suitable for flour/atta/maida/sooji, spice powders (chilli, turmeric, masala), sugar, salt, tea/coffee, milk powder, chemicals, detergent powder, and herbal/pharma powders before mixing or packing. |

| Electric Motor | 0.5 HP Vibro Motor |

| Motor Brand | Mill Power |

| Phase | Three Phase |

| Voltage | 440V, 50Hz |

| Power Consumption | 0.36 kWh (0.36 Units/hr) |

| Chamber Size | 30" Diameter |

| Body Structure | MS & SS304 Food Grade contact parts |

| Food Grade | Full body SS304 Food Grade also available |

| Weight | 100 kg |

| Dimension (LxWxH) | 2' x 2' x 3' (feet) |

Model Range

| VS24 | 24" Diameter Sieve, 0.5 HP Vibro Motor Three Phase |

|---|---|

| VS30 | 30" Diameter Sieve, 0.5 HP Vibro Motor Three Phase |

| VS36 | 36" Diameter Sieve, 0.5 HP Vibro Motor Three Phase |

| VS48 | 48" Diameter Sieve, 0.5 HP Vibro Motor Three Phase |

| VS60 | 60" Diameter Sieve, 0.5 HP Vibro Motor Three Phase |

| VS72 | 72" Diameter Sieve, 0.5 HP Vibro Motor Three Phase |